Det ser ut som att du är i USA

Vi har en annan sida (www.q-bital.com) som bättre passar din plats

One common preconception is that flexible healthcare facilities are cramped. But although they may have a smaller footprint than a hospital’s existing theatres and fit onto the back of a truck, mobile operating theatres are expandable and surprisingly spacious inside. Where larger facilities or hybrid operationssalar are required, a modular facility of almost any size can be made bespoke to individual requirements.

Our mobile and modular units are also designed with efficiency and patient flow in mind. The facilities are carefully thought out to ensure there is sufficient space for key activities in both the main procedure rooms, and throughout the supporting areas.

While it is true that ancillary space is often limited within mobile facilities, a connection can usually be made to link with the existing department within the main hospital building, or it can be combined with modular units to create a self-contained complex. Modular buildings can house changing facilities and staff rest areas as well as a reception, a patient waiting area and washroom facilities - or even a complete ward - creating a stand-alone complex.

Although mobile and modular units are pre-fabricated and can be put into place quickly, that doesn’t mean quality has been compromised. Mobile theatres are sophisticated facilities. They take a long time to build and they undergo rigorous testing before being made available to clients. Between contracts, units are brought back to for any necessary maintenance and refurbishment work to be done and for checks to be performed.

Mobile facilities are built to last; one of Vanguard’s operating theatres, used for major orthopaedic joint surgery, was at the same site for more than 10 years as an integral part of the hospital’s estate. Another, used for podiatry and hand surgery, saw the contract extend multiple times with over 5,200 procedures performed in total in the facility over the 10 years it was in place.

Similarly, the fact that modular facilities can be built and installed quickly doesn’t necessarily mean that quality is compromised. In fact, it can be the opposite - producing the facilities in a factory controlled environment means it is easier to assure build quality and adherence to standards, and units are extensively inspected before leaving the factory. While offered as a temporary solution, they are designed for permanent use. Modular facilities are robustly constructed from steel frames with concrete floors giving a life expectancy in excess of 60 years, during which the facilities can be repurposed and relocated multiple times according to changing needs.

There is a big difference between mobile and modular operating theatres and portable buildings used as accommodation for building projects or temporary classrooms.

Temporary operating theatres, endoscopy suites and sterilisation or decontamination units are complex facilities which have been specifically designed for their purpose. They are often built to the same standard as permanent healthcare buildings, come with features such as modern lighting and specialist equipment needed to perform the procedures. In some cases, the equipment in the unit can be more high-tech than that in the main hospital.

The facilities have been designed to be high-performing, safe and compliant with all relevant regulations from the start. Theatres have specialist on board systems such as HEPA filtered air that conforms to EU Grade C, treated water, and integral MGPS systems where required.

Prior to the contract starting, a full validation and commissioning programme is carried out, which includes air quality testing, water validation, electrical testing and validation of any equipment, for example washers and sterilisers. Facilities are also regularly maintained and serviced.

Although it may be smaller than the in-hospital theatre department, the inside of a temporary theatre is designed for efficiency and the internal environment is closely monitored. Theatres come with air conditioning and are designed to be comfortable for both patients and staff.

It is common to hear from staff and patients that they are surprised at how spacious and airy the facility feels when inside. Feedback received also suggests the units are brighter than anticipated.

Sterilisation and decontamination staff working in our CSSD units also like the fact the space is well laid out for efficient instrument flow, and that the unit has natural light and windows to the outside – something of a luxury since sterilisation departments are often located in the basement.

There can be a lack of staff welfare areas, such as showers, rest and changing areas and coffee making facilities, but there is always the option to connect the facility to either the main hospital or a separate module that can provide this. A modular facility can be designed to the hospitals exact specifications.

Staff may be apprehensive about treating patients in an area away from the main hospital building, where immediate support and help are at hand in the case of an emergency. However, medical emergencies are discussed and action plans considered in advance. Processes for patient emergencies, evacuations and other unplanned events, such as a fire, are agreed and incorporated into plans before any patients attend the facility.

When a new contract is signed, Vanguard will hold an Operational Delivery Meeting, during which work practices and responsibilities for the project are agreed, enabling all involved parties to make appropriate preparations. A full project plan will also be issued to limit the impact of installation and will be signed off by both parties ahead of activity on the facility.

The fact the facility is remote from the rest of the hospital can also be a concern, but having a stand-alone facility away from the main areas of the hospital where patients can be treated in isolation has proven to be a benefit during the pandemic.

Similarly, there is often concern around the patient journey. Depending on where the unit is situated, this may be an issue, but Vanguard can work with the hospital’s estates and clinical teams to find the most suitable solution for transporting patients to and from the facility.

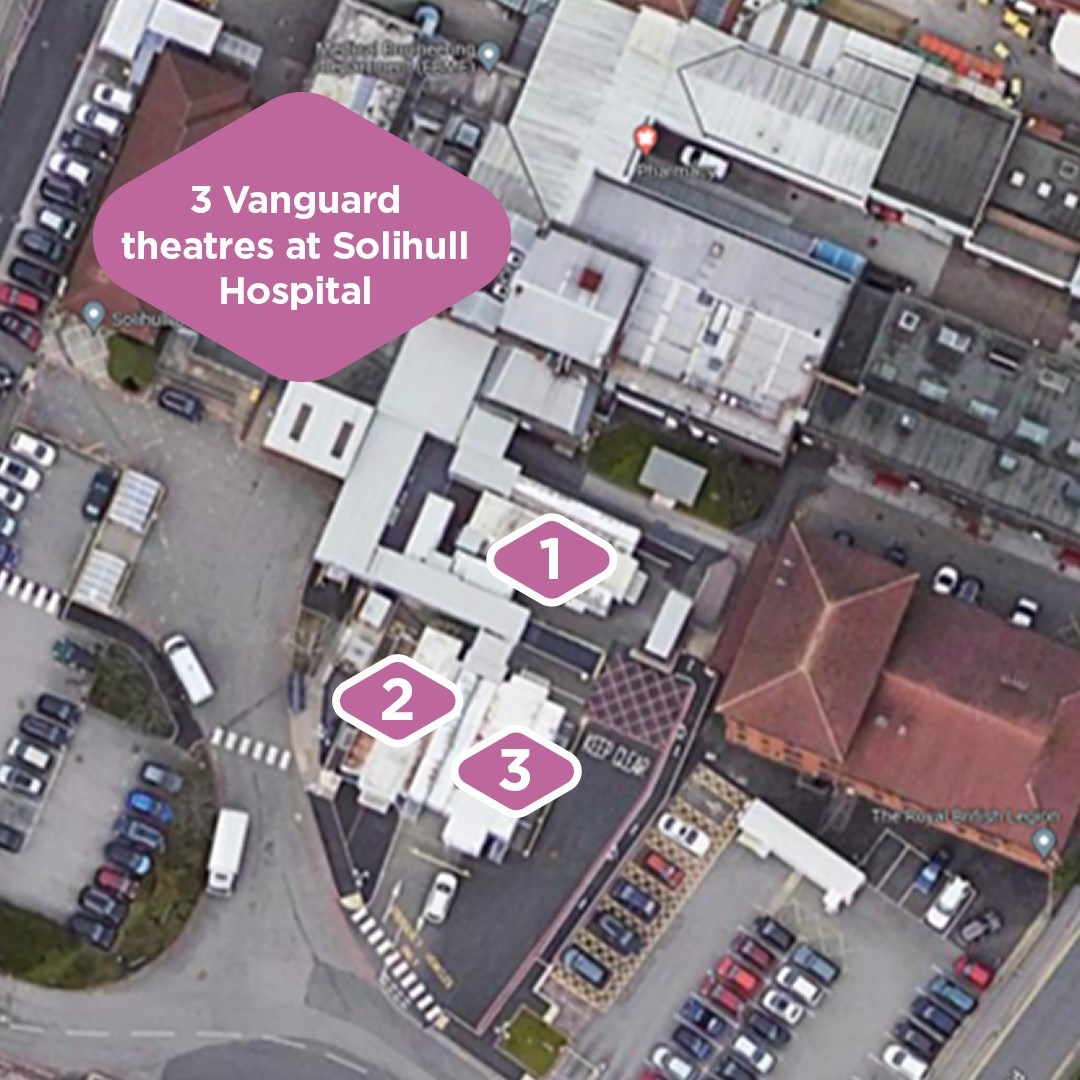

In cases where the main operating department is very far from an external entry point, or for day surgery cases, it may be beneficial to create a stand-alone small complex or ‘visiting hospital’, consisting of one or more theatres together with modules containing all required patient and staff areas; and perhaps a mobile or modular ward.

This means patients can be admitted directly onto the facility, have their procedure, recover and then be discharged directly from the facility at the end, all without entering the main hospital – something which has been a key benefit during Covid.

In addition, having patients coming directly to the unit can lead to more effective use of time in theatres as time spent waiting for patients to be transferred from other areas of the hospital is cut. Efficiency gains can be made when everything is closer to hand.

Understandably, staff can become concerned about working in a new environment or with unfamiliar equipment, and away from other colleagues. Moving to another facility on a temporary basis will inevitably mean surgeons need to go out of their comfort zone to some extent.

As far as is practical, routines and working practices in the temporary facility will be made to fit with the working practices already in place. Vanguard offers induction sessions for staff and full training on any unfamiliar equipment.

With bespoke modular solutions, there is an opportunity for the hospital’s facilities’ and clinical teams to be involved in creating specifications for the temporary facility, which can aid the transfer of existing operations into the temporary unit. It works the other way too - where a facility is being used to provide capacity during a larger refurbishment or newbuild project, a modular complex can be used to test out new routines and working practices in preparation for a move to the new facility.

Mobile healthcare facilities are designed specifically to be able to connect with existing hospitals’ own infrastructure quickly and easily. Our central sterilisation departments, for example, come with inbuilt integration for the client’s own track-and-trace system. But while the same operating theatre or other clinical facility can be moved between hospitals and serve different health providers, some customisation is often required.

All hospitals are different, and each customer has different needs and different ways of working. Vanguard works in close partnership with each customer, and based on our extensive experience of working with health providers worldwide, we aim to achieve the optimal configuration and set-up in each case.

A thorough site survey is undertaken and suggestions are provided for the best way forward with regards to a range of issues, including utilities connections and integrations with IT and fire and security systems. Occasionally a modular building, built bespoke to the client’s exact requirements may be the answer.

Although rarely of major concern for facilities managers, in some cases this can be an important issue. For example, when situated in a very visible location to the general public, such as near the main entrance, or where it will be overlooked by private housing.

The mobile unit may not fit in with the look of the rest of the hospital, depending on what the rest of the site looks like and whether it has other temporary buildings on it. Our mobile units are clean and bright and come with a skirt to cover up the area below the unit, making it look more permanent. Units can be customised with ramps, steps, walkways and additional buildings to fit with the look of the rest of the hospital.

A modular building or complex can be made to look however the client wishes it to. The type, material and colour of the exterior, as well as flooring and curtains on the inside, can be customised if required to fit with the overall look and feel of the existing hospital.

Last but not least, there is sometimes a concern that patients will be unwilling to be treated in a temporary unit. In our experience, however, patients are generally happy to be treated in any suitable space.

In fact, the experience has been the opposite during the pandemic - patients have been happier coming to a stand-alone facility without the need to enter the main hospital building. This has meant that even high-risk patients have been able to attend scheduled elective procedures or scans.

The key to reassuring patients and managing their expectations is effective communication. Patients are, on the whole, accepting of receiving treatment in any type of building, but it is important to keep them informed. The way this information is relayed to patients is also important; clearly patients will be less content if they turn up to the usual operating department and are then told to go ‘round the back’ to the temporary facility outside in the car park.

Pre-arrival communication is most effective when it details where the building is located within the hospital campus and there is clear, concise signage to the temporary building. In most cases, patients are happy that the hospital has taken steps to increase capacity so that the waiting time for their procedure could be reduced.

Overall, the feedback we get from both staff and patients is overwhelmingly positive. We sometimes hear from clients that they were initially unsure how well it would work and that staff were apprehensive, only to find using and working in the unit have exceeded their expectations. The initial concerns are mostly about the ‘fear of the unknown’.

As already mentioned, communication is extremely important in providing reassurance; about the physical characteristics, compliance and quality of the facility, as well as from a clinical perspective. Not just in terms of communicating with patients – communication between facilities teams and the staff that will be working in the new facility is also important.

Another key word is ‘flexibility’. A temporary healthcare facility is not just a building - it provides a flexible solution to a capacity issue. Vanguard Healthcare Solutions has more than 20 years’ experience of adapting to different clients’ unique needs, and as such, concerns can often be addressed and a solution can often be found, as long as they are communicated at an early stage.

Komma i kontakt if you would like to discuss any concerns or find out more about flexible healthcare.

Vanguard Healthcare Solutions

Unit 1144 Regent Court, The Square, Gloucester Business Park, Gloucester, GL3 4AD

Vi har en annan sida (www.q-bital.com) som bättre passar din plats